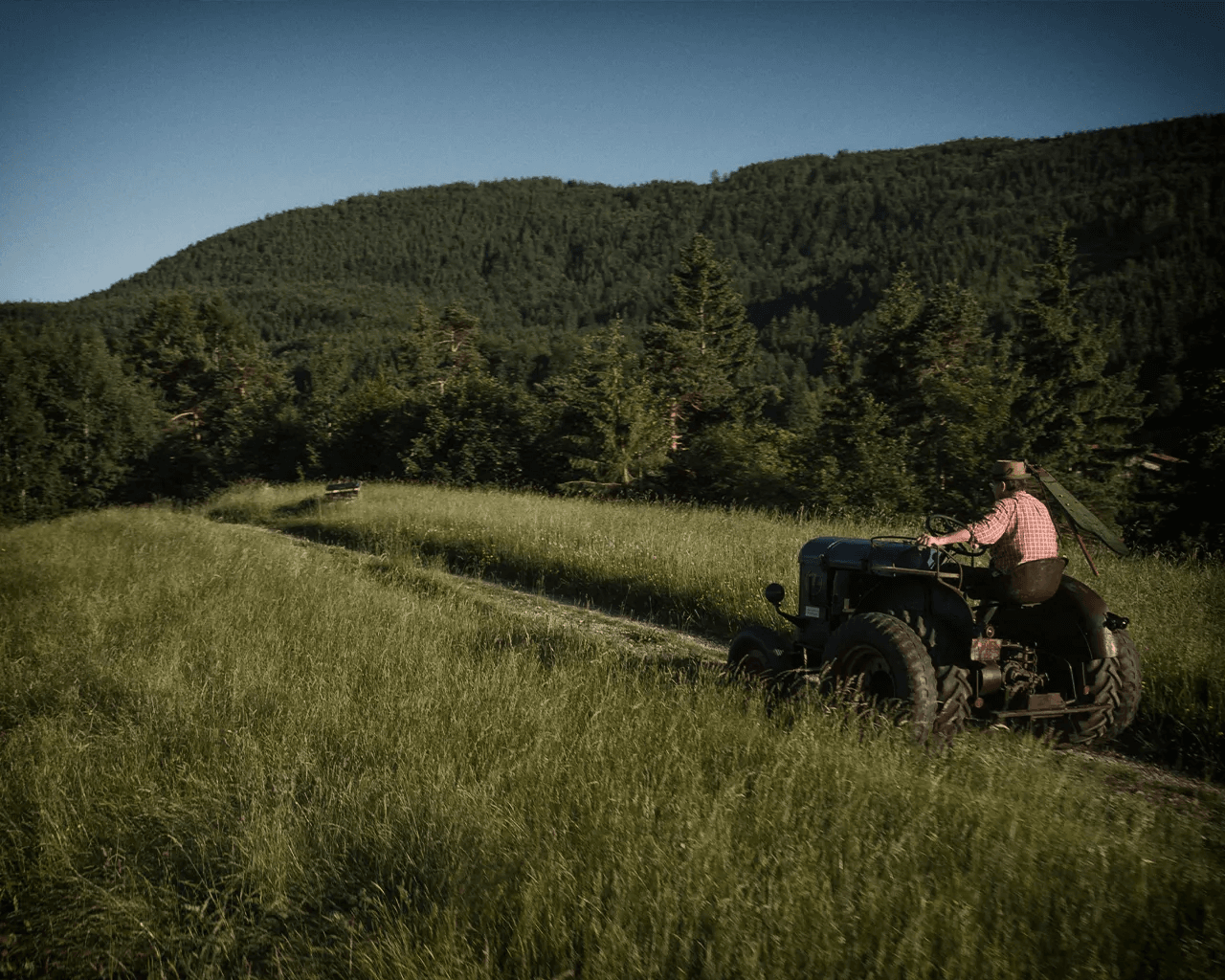

01 Regional raw materials, short distances

Our barley comes from the north-east of Munich, where the best conditions for spring barley prevail - in conventional and organic quality. We cultivate the yeast in our own tank to ensure consistently high quality. Our barrels made from American white oak accompany us for up to 25 years before they are given a second life at breweries or wineries. Production residues such as spent grain are returned to the regional cycle as animal feed.

02. Energy reimagined

Our new distillery is designed around an energy concept—not the other way around. A high-temperature heat pump provides process heat of over 100 °C, while photovoltaics and heat recovery systems drastically reduce energy consumption. Two-thirds of our electricity comes from our own PV systems, with the rest supplied by a third-party eco-electricity provider. We now use fossil fuels only to a very limited extent – solely to start up the process. After that, production runs entirely on a regenerative basis.

03 Water: a resource with respect

Whisky consists largely of water - and that's exactly how we treat it. Thanks to the new construction of our production plant, we save around 200,000 liters of cooling water every year. Closed circuits and modern heat exchangers make consumption highly efficient. This means that the water remains what it should be for us: A source of taste, not a means of wear and tear.

04. Consciously packaged

For us, sustainability does not end with whisky. Our shipping packaging is plastic-free, labels are made of paper and we use 100% recycled glass and Gmund Bio Cycle paper made from renewable raw materials for our organic whisky line. Every bottle represents how we handle materials with responsibility — down to the smallest detail.

05. Responsibility for people

Sustainability also means social responsibility. We are a certified family-friendly employer and a member of the Bavarian Family Pact. Over half of our management staff are women, many of whom work part-time or flexible hours. We train our own distillers and other employees, support further qualifications, and offer a sustainable mobility alternative in the form of the Business Bike program, which has been enthusiastically received.

06 Sustainability as a systematic approach

At SLYRS, we see sustainability as a holistic principle — it shapes everything we do, from the initial idea to the finished product. From Bavarian grain to the bottle, from modern technology to the people behind the craft, we think in closed cycles. Ecology, economy, and social responsibility intertwine to form a system that combines efficiency, quality, and awareness—in harmony with nature and the region we call home